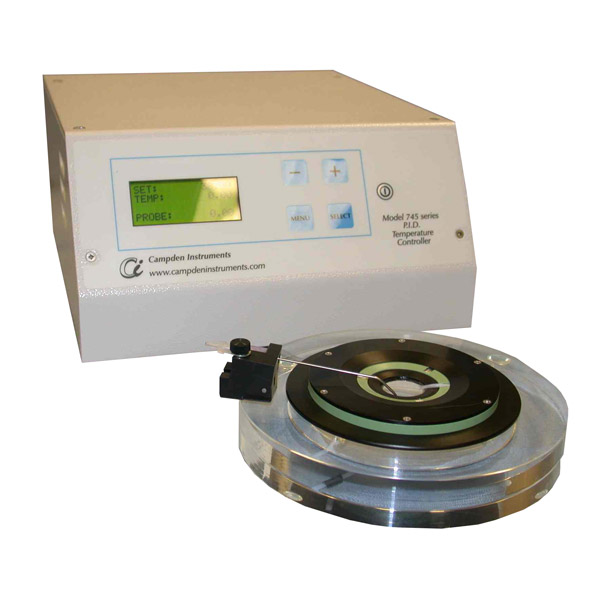

Visual Patching and Imaging Chamber

Model 7800

Consists of an aluminium heat exchanger plate heated by a thin heating element. The heat exchanger supplies concentric heat to the chamber itself and in-line heat to the incoming perfusate ensuring both are heated uniformly.

The 7800 Visual Patching and Imaging Chamber consists of an aluminium heat exchanger plate heated by a thin heating element. The heat exchanger supplies concentric heat to the chamber itself and in-line heat to the incoming perfusate ensuring both are heated uniformly. A thermistor embedded in the plate gives temperature feedback to the control system. In its upper surface the plate has a series of annular grooves to carry up to four perfusate tubes. The perfusate tubes carry perfusate to the central chamber at very low level encouraging laminar flow across the chamber.

A gas inlet port allows gas to be introduced for hypoxia studies. Gas flows around the grooves and is heated, eventually exhausting into the central chamber through radial grooves. The heat exchanger plate is coated on all surfaces with p.t.f.e. to discourage drug adhesion. Considerable attention in the design stage has resulted in a chamber with a very low profile reducing the likelihood of the unit interfering with the objective lens and instrumentation probes, electrodes, etc. Because the unit is very compact, the heater output has been closely balanced to the thermal mass of the heat exchanger and the likely demands of perfusate / gas flow. The unit should therefore be protected as much as possible from outside influences such as cold draughts, open doors and windows that may cause unexpected and unwanted variations in temperature.

The temperature controller using PID (Proportional Integral Derivative) algorithms allows close control of the perfusate temperature to within +/- 0.1° C. A second temperature feedback probe can be placed in the central chamber and connected to the controller allowing both chamber temperature and temperature offset (between perfusate and chamber) to be established. The controller has analogue data output capabilities. All power outputs from the controller are DC ensuring that there are no electromagnetic noise emissions to interfere with other instrumentation.

A unique design of suction capillary tube ensures a steady flow of waste perfusate from the centre chamber whilst maintaining a smooth, constant level of perfusate in the centre chamber. The suction tube is adjustable for perfusate depth and has a low profile to avoid interference with other instrumentation probes.

The heat exchanger plate is designed to accept a 22mm slip carrier (along with a vented, double glazed cover if required for hypoxia studies) or a 35mm Petri type dish. Additional slip carriers and chambers to special designs are available on request.

The heat exchanger is mounted on the microscope stage via an insulating adapter ring. The adapter ring has location diameters of 108mm and 110mm making the unit suitable for the majority of upright and inverted microscopes. Other adapter rings to suit a particular microscope can be supplied on request.

Features

CHAMBER

- Easy to use: Just put it on the microscope stage, plug in the controller, connect the tubing and switch it on

- High temperature stability at flow rates of 2-3 ml / sec, from combined in-line and concentric temperature control

- Low profile for easy access of electrodes under the heated objective lens when mounted on upright microscopes.

- No electromagnetic noise emission from the DC power source.

- Annular ring adapter to fit all types of upright and inverted microscopes

- Adapts to 22mm coverslip or 35mm petri dish

- Laminar flow of fluids across the center of the chamber

- 1ml/minutes flow rates

- Used for fever studies at 42° Celsius

- Chambers are coated with chemically inert p.t.f.e. (Teflon®) to avoid adhesion of drugs.

- Gas inlet through heat exchanger into chamber for hypoxia studies, hydrophobic p.t.f.e. resists flooding into gas inlets.

- Unique design of suction capillary ensures a steady state of flow and a mill pond smooth surface in a shallow pool of 1mm depth.

- Ag/AgCl reference wire is simply placed within the chamber

- Vented lid seals the chamber for hypoxia studies

TEMPERATURE CONTROLLER

- Predictive algorithms [proportional integral derivative] gives very close control of temperature to +/- 0.1 Celsius

- Configurable alarms for temperature envelopes

- No electromagnetic noise emission from the DC power source

- Temperature feedback from 2 thermistor probes, one can be placed in the chamber to check temperature, the other is permanently embedded with the perfusate tubes in the body of the chamber.

- Digital and analog data outputs are available